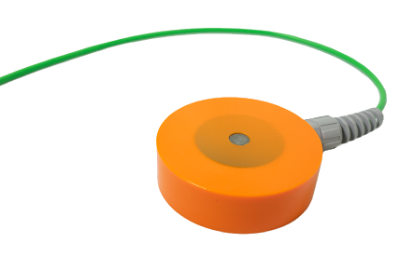

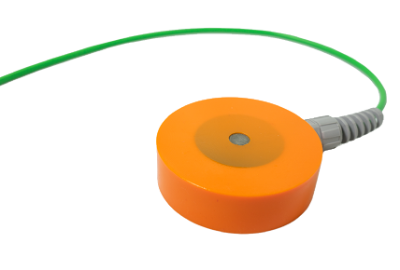

AC COUPON ACC3 CSCL

-

AC COUPON 1cm² BARE STEEL, 20 MIL COATING THICKNESS, 5m #12/7 STR RWU90 GREEN LEAD

Features & Benefits

- Improved ability to simulate coating holidays due to the customizable coating thickness 20 mils, 40 mils, 80 mils or custom to meet customer's project demands.

- Coating holiday size 1 cm2 or 1 in2.

- Non-conductive surface surrounding the bare area optimized to limit electrical field distortion while maintaining a compact installation size.

- Designed to allow for coupon pointing up placement to match the orientation of coating holidays with the highest AC current densities. + Weighted steel core with removable coating for corrosion rate measurements as per ASTM G1-03.

- Stamped with a serial number protected from corrosion for improved traceability

- Accurate AC corrosion risk assessment to avoid unnecessary mitigation costs.

- Regular monitoring provides the pipeline operator with historical and current operating conditions, identifies areas requiring AC mitigation, and validates the effectiveness of AC mitigation systems.

- Improved ability to simulate corrosion rates by allowing for the lateral extension of the corrosion pit under the coating.

- Compatible with remote monitoring and conventional survey equipment.

- Compatible with new and existing test stations

Code: ACC3AAVAILABLEQuebec Online Orders Not Available -

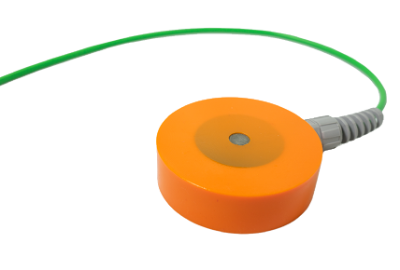

AC COUPON 1cm² BARE STEEL, 20 MIL COATING THICKNESS, 10m #12/7 STR RWU90 GREEN LEAD

Features & Benefits

- Improved ability to simulate coating holidays due to the customizable coating thickness 20 mils, 40 mils, 80 mils or custom to meet customer's project demands.

- Coating holiday size 1 cm2 or 1 in2.

- Non-conductive surface surrounding the bare area optimized to limit electrical field distortion while maintaining a compact installation size.

- Designed to allow for coupon pointing up placement to match the orientation of coating holidays with the highest AC current densities. + Weighted steel core with removable coating for corrosion rate measurements as per ASTM G1-03.

- Stamped with a serial number protected from corrosion for improved traceability

- Accurate AC corrosion risk assessment to avoid unnecessary mitigation costs.

- Regular monitoring provides the pipeline operator with historical and current operating conditions, identifies areas requiring AC mitigation, and validates the effectiveness of AC mitigation systems.

- Improved ability to simulate corrosion rates by allowing for the lateral extension of the corrosion pit under the coating.

- Compatible with remote monitoring and conventional survey equipment.

- Compatible with new and existing test stations

Code: ACC3BAVAILABLEQuebec Online Orders Not Available -

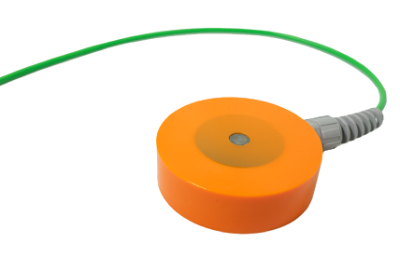

AC COUPON 1cm² BARE STEEL, 20 MIL COATING THICKNESS, 15m #12/7 STR RWU90 GREEN LEAD

Features & Benefits

- Improved ability to simulate coating holidays due to the customizable coating thickness 20 mils, 40 mils, 80 mils or custom to meet customer's project demands.

- Coating holiday size 1 cm2 or 1 in2.

- Non-conductive surface surrounding the bare area optimized to limit electrical field distortion while maintaining a compact installation size.

- Designed to allow for coupon pointing up placement to match the orientation of coating holidays with the highest AC current densities. + Weighted steel core with removable coating for corrosion rate measurements as per ASTM G1-03.

- Stamped with a serial number protected from corrosion for improved traceability

- Accurate AC corrosion risk assessment to avoid unnecessary mitigation costs.

- Regular monitoring provides the pipeline operator with historical and current operating conditions, identifies areas requiring AC mitigation, and validates the effectiveness of AC mitigation systems.

- Improved ability to simulate corrosion rates by allowing for the lateral extension of the corrosion pit under the coating.

- Compatible with remote monitoring and conventional survey equipment.

- Compatible with new and existing test stations

Code: ACC3CAVAILABLEQuebec Online Orders Not Available -

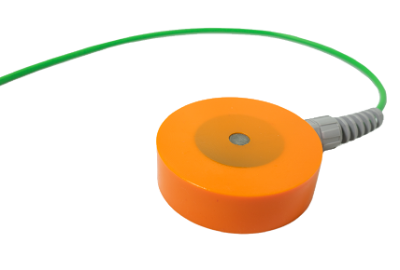

AC COUPON 1cm² BARE STEEL, 20 MIL COATING THICKNESS, 20m #12/7 STR RWU90 GREEN LEAD

Features & Benefits

- Improved ability to simulate coating holidays due to the customizable coating thickness 20 mils, 40 mils, 80 mils or custom to meet customer's project demands.

- Coating holiday size 1 cm2 or 1 in2.

- Non-conductive surface surrounding the bare area optimized to limit electrical field distortion while maintaining a compact installation size.

- Designed to allow for coupon pointing up placement to match the orientation of coating holidays with the highest AC current densities. + Weighted steel core with removable coating for corrosion rate measurements as per ASTM G1-03.

- Stamped with a serial number protected from corrosion for improved traceability

- Accurate AC corrosion risk assessment to avoid unnecessary mitigation costs.

- Regular monitoring provides the pipeline operator with historical and current operating conditions, identifies areas requiring AC mitigation, and validates the effectiveness of AC mitigation systems.

- Improved ability to simulate corrosion rates by allowing for the lateral extension of the corrosion pit under the coating.

- Compatible with remote monitoring and conventional survey equipment.

- Compatible with new and existing test stations

Code: ACC3DQUICK SHIP AVAILABLEQuebec Online Orders Not Available -

AC COUPON 1cm² BARE STEEL, 20 MIL COATING THICKNESS, 25m #12/7 STR RWU90 GREEN LEAD

Features & Benefits

- Improved ability to simulate coating holidays due to the customizable coating thickness 20 mils, 40 mils, 80 mils or custom to meet customer's project demands.

- Coating holiday size 1 cm2 or 1 in2.

- Non-conductive surface surrounding the bare area optimized to limit electrical field distortion while maintaining a compact installation size.

- Designed to allow for coupon pointing up placement to match the orientation of coating holidays with the highest AC current densities. + Weighted steel core with removable coating for corrosion rate measurements as per ASTM G1-03.

- Stamped with a serial number protected from corrosion for improved traceability

- Accurate AC corrosion risk assessment to avoid unnecessary mitigation costs.

- Regular monitoring provides the pipeline operator with historical and current operating conditions, identifies areas requiring AC mitigation, and validates the effectiveness of AC mitigation systems.

- Improved ability to simulate corrosion rates by allowing for the lateral extension of the corrosion pit under the coating.

- Compatible with remote monitoring and conventional survey equipment.

- Compatible with new and existing test stations

Code: ACC3EAVAILABLEQuebec Online Orders Not Available